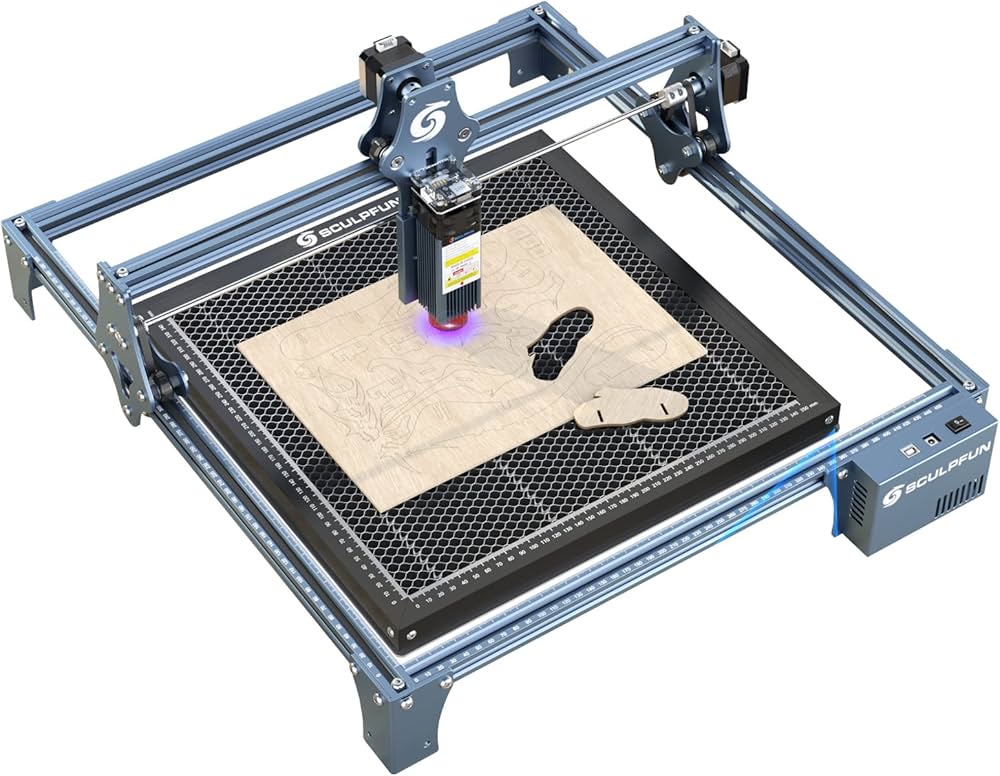

From the creativity of engineering to the precision of laser cutters, explore how technology is revolutionizing cutting machines. Discover why these powerful tools are allowing craftspeople to achieve a level of accuracy and detail never before possible.

Learn about the latest advancements in laser cutting machine technology, from their state-of-the-art components to their versatility in a range of industries and applications. Uncover what makes them stand out from traditional methods and see how they can take your projects to the next level.

Precision Unleashed: Exploring The World Of Laser Cutting Machines digs deep into this fascinating topic, providing an insightful look at its potential for todays modern world.

Uncovering the Benefits of Laser Cutting Machines

Laser cutting machines are an invaluable tool for modern manufacturing, providing businesses with precision that has never been seen before. From intricate designs to complex shapes, the potential of laser-driven technology is far-reaching and helps create products with incredible accuracy.

By leveraging this advanced machinery, companies can produce high-quality items while also reducing costs and saving valuable time in the process. The benefits of using a laser cutter go beyond merely creating products quicker or more accurately.

Laser cutters provide greater flexibility when it comes to customizing projects for specific needs, allowing businesses to deliver unique solutions without having to make costly investments in additional equipment or specialized personnel. Furthermore, by utilizing the power of lasers these tools have become essential components within many production processes as they are capable of working on multiple types of materials such as wood, metal, glass and plastics – all at once! In addition to increased efficiency and cost savings achieved through their use, there is another major benefit associated with laser cutting machines; they offer improved safety compared to traditional methods like saws or drills which require manual handling.

By eliminating direct human contact from certain operations there is much less risk involved when working with materials that may contain hazardous particles or gases released during operation. This makes them highly suitable for use in medical environments where sterility must be maintained at all times! These machines have revolutionized how we manufacture products today and opened up new possibilities for businesses looking to improve their processes while still maintaining quality standards.

With so many advantages associated with their use it’s easy to see why laser cutters have become a fixture in numerous industries around the world – uncovering the true potential hidden beneath their sleek exterior!

Exploring the Science Behind Laser Cutting Technology

Source: www.amazon.comLaser cutting technology has revolutionized the world of precision engineering and manufacturing. By harnessing the power of lasers, machines can now achieve levels of accuracy that would have been unimaginable just a few decades ago. But what makes laser cutting unique, and how does it work? In this article, we explore the science behind laser cutting technology to shed light on its inner workings.

Source: www.amazon.comLaser cutting technology has revolutionized the world of precision engineering and manufacturing. By harnessing the power of lasers, machines can now achieve levels of accuracy that would have been unimaginable just a few decades ago. But what makes laser cutting unique, and how does it work? In this article, we explore the science behind laser cutting technology to shed light on its inner workings.

At its core, laser cutting is all about controlling energy in precisely targeted ways. The beam produced by a laser cutter is incredibly powerful yet extremely precise; capable of producing shapes with incredible detail in materials such as wood or metal without damaging surrounding areas.

To do this effectively requires complex systems for focusing and controlling the beams intensity at any given point – something which traditional tools cannot compete with when it comes to accuracy. The way these beams interact with different materials also plays an important role in determining their effectiveness when used for precision cuts like those required in many modern industrial applications.

Different materials absorb light differently, meaning that finding just the right settings for each one is key to achieving smooth edges without leaving any debris behind or causing damage elsewhere on the material itself. As such, understanding not only how lasers operate but also how they interact with specific substances helps manufacturers ensure that every cut meets their exact requirements every time they use their machine(s).

Finally, there are certain safety measures that must be taken into consideration when using laser cutters due to their highly concentrated beams and potential risks associated with them if handled incorrectly or carelessly operated by unskilled personnel (or even poorly designed machines). Its essential to understand both preventative measures as well as best practices around operation before attempting any kind of work involving potentially hazardous equipment like this one – something which even trained technicians should never take lightly!

Examining the Different Types of Laser Cutters Available

Source: www.thefabricator.comWhen it comes to laser cutting, there is no one-size-fits-all approach. Different types of laser cutters are available on the market, each offering unique capabilities and advantages.

Source: www.thefabricator.comWhen it comes to laser cutting, there is no one-size-fits-all approach. Different types of laser cutters are available on the market, each offering unique capabilities and advantages.

From basic handheld craft lasers to large industrial machines, the range of options can feel overwhelming when trying to decide which type best suits your project needs. In this article, well take a closer look at some of the different types of laser cutters available today and discuss how each can help you unleash precision in your projects.

CO2 Lasers are the most common type found in both commercial and hobby applications due to their versatility and affordability. These lasers use a gas mixture containing carbon dioxide as its primary source for energy production, allowing them to generate high power outputs with great accuracy levels.

CO2 Laser Cutters deliver smooth cuts through many materials ranging from paperboard up to thicker metals like stainless steel or aluminum alloys – making them an ideal choice for versatile projects such as signage and engraving work. Fiber Lasers provide powerful performance with excellent beam quality at longer ranges than other laser sources, making them perfect for larger scale operations that require higher power output over greater distances than what CO2 lasers offer.

High speeds combined with extreme accuracy allow fiber lasers to easily produce intricate shapes even on thick metal plates without requiring additional finishing treatments afterward – perfect for medical device manufacturing or any mass production tasks that demand precision results quickly! Crystal Lasers represent another class of advanced technology specifically designed for high speed cutting jobs requiring extremely precise results within tight tolerances and miniscule detail resolution capabilities. For ultrafast throughputs coupled with outstanding edge quality – crystal laser systems remain unmatched in terms of performance per watt compared against traditional CO2 based solutions; making them ideal candidates whenever time efficiency is key! Finally, Diode Pumped Solid State (DPSS) Lasers combine several technologies into one compact package capable of producing exceptional marking results while consuming minimal amounts of electricity when compared against more conventional solutions such as Fiber or Crystal models mentioned above; thus providing an attractive alternative especially suitable for small business owners who need reliable equipment without breaking the bank!

Conclusion

Laser cutting machines have revolutionized the manufacturing industry by providing precision like never before. They are capable of creating intricate shapes and patterns with accuracy, thereby reducing wastage and increasing efficiency.

Laser cutting machines are perfect for both small to large scale production as they can be easily programmed to produce complex designs. Their ability to deliver accurate results in a short period of time makes them ideal for businesses that need quick turnaround times on their projects.

Overall, laser cutting machines have unleashed a new level of precision in the world of manufacturing, making it easier than ever before for businesses to create unique products quickly and efficiently.