In the fast-paced world of modern manufacturing, CNC lathes have emerged as game-changers, revolutionizing the way products are produced. These advanced machines have transformed the production process, allowing manufacturers to create intricate and precise components with unmatched speed and accuracy.

With the advent of CNC technology, the possibilities in manufacturing have become endless, paving the way for a new era of innovation and efficiency. This article will delve into the impact of CNC lathes on modern production, exploring how these cutting-edge machines are reshaping the manufacturing industry.

Advantages of CNC Lathes in Production

The advantages of CNC lathes in production are numerous and far-reaching. Firstly, CNC lathes provide unmatched precision and consistency in manufacturing processes, leading to higher quality end-products.

This precision also allows for increased efficiency in production, as it reduces the need for manual adjustments and minimizes the risk of errors. Additionally, CNC lathes offer greater versatility in terms of the range of shapes and sizes that can be produced, enabling manufacturers to meet a wider variety of customer demands. Furthermore, the automation capabilities of CNC lathes can lead to significant cost savings over time, as it reduces the need for manual labor and increases overall productivity.

In short, the impact of CNC lathes on modern production cannot be overstated, as they revolutionize the manufacturing process in countless ways.

Increased Efficiency and Precision with CNC Lathes

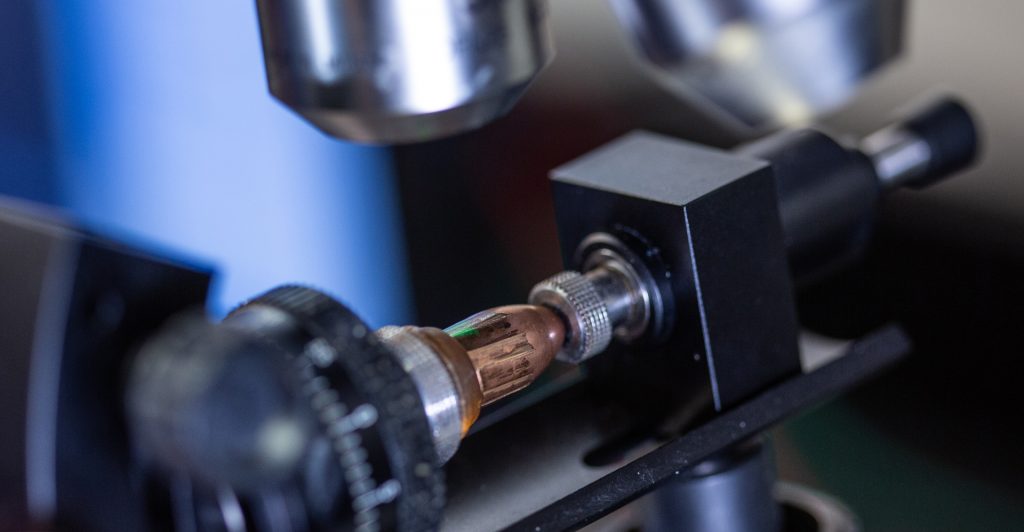

Source: www.3erp.comIncreased efficiency and precision are two key benefits of utilizing CNC lathes in modern manufacturing processes. These advanced machines are capable of producing complex parts with tight tolerances at a much faster rate than traditional manual lathes.

Source: www.3erp.comIncreased efficiency and precision are two key benefits of utilizing CNC lathes in modern manufacturing processes. These advanced machines are capable of producing complex parts with tight tolerances at a much faster rate than traditional manual lathes.

By automating the turning process, CNC lathes eliminate human error and ensure consistent quality in every part produced. This not only reduces production time but also minimizes waste and rework, ultimately leading to cost savings for manufacturers.

Additionally, CNC lathes allow for greater flexibility and customization, as they can easily switch between different part designs without the need for extensive retooling. Overall, the integration of CNC lathes into production lines has revolutionized the way manufacturers approach machining, resulting in higher productivity and improved overall efficiency.

Impact of CNC Lathes on Modern Production Processes

Source: www.beckhoff.comThe impact of CNC lathes on modern production processes cannot be understated. These advanced machines have revolutionized the manufacturing industry by allowing for greater precision, consistency, and efficiency in the production of complex parts. With CNC lathes, manufacturers can produce intricate components with minimal human intervention, reducing the risk of errors and improving overall quality.

Source: www.beckhoff.comThe impact of CNC lathes on modern production processes cannot be understated. These advanced machines have revolutionized the manufacturing industry by allowing for greater precision, consistency, and efficiency in the production of complex parts. With CNC lathes, manufacturers can produce intricate components with minimal human intervention, reducing the risk of errors and improving overall quality.

Additionally, CNC lathes have significantly shortened production times, enabling companies to meet tight deadlines and increase their output. Overall, the introduction of CNC lathes into modern production processes has transformed the way components are manufactured, leading to higher productivity and enhanced competitiveness in the global market.

Case Studies on Successful Implementation of CNC Lathes

Source: jtektmachinery.comCase studies have shown that the successful implementation of CNC lathes has revolutionized modern production processes in several industries. One such case study involved a manufacturing company that saw a significant increase in productivity and efficiency after switching from traditional manual lathes to CNC lathes.

Source: jtektmachinery.comCase studies have shown that the successful implementation of CNC lathes has revolutionized modern production processes in several industries. One such case study involved a manufacturing company that saw a significant increase in productivity and efficiency after switching from traditional manual lathes to CNC lathes.

By automating the machining process, the company was able to produce higher-quality parts at a faster rate, leading to reduced lead times and increased customer satisfaction. Another case study highlighted the cost-saving benefits of CNC lathes, with a company reporting a substantial decrease in waste material and rework expenses.

Overall, these case studies showcase the transformative impact that CNC lathes can have on manufacturing operations, paving the way for a more streamlined and profitable future.

Future Trends in CNC Lathe Technology

Source: forensicstats.orgAs technology continues to advance, the future of CNC lathe technology is poised to revolutionize modern production processes in unprecedented ways. One key trend on the horizon is the integration of artificial intelligence and machine learning algorithms into CNC lathes, allowing for real-time adjustments and optimizations based on data analysis.

Source: forensicstats.orgAs technology continues to advance, the future of CNC lathe technology is poised to revolutionize modern production processes in unprecedented ways. One key trend on the horizon is the integration of artificial intelligence and machine learning algorithms into CNC lathes, allowing for real-time adjustments and optimizations based on data analysis.

Additionally, the development of hybrid machines that combine additive manufacturing capabilities with traditional subtractive processes is expected to bring about new possibilities in the manufacturing industry. These advancements are set to enhance precision, efficiency, and flexibility in CNC lathe operations, paving the way for even greater innovation and productivity in the years to come.

Conclusion

Source: medium.comIn conclusion, the advent of CNC lathes has truly revolutionized the manufacturing industry, providing increased efficiency, precision, and versatility in modern production processes. These advanced machines have not only allowed for the creation of complex and intricate parts with incredible accuracy but also have streamlined the manufacturing process, reducing production times and costs.

Source: medium.comIn conclusion, the advent of CNC lathes has truly revolutionized the manufacturing industry, providing increased efficiency, precision, and versatility in modern production processes. These advanced machines have not only allowed for the creation of complex and intricate parts with incredible accuracy but also have streamlined the manufacturing process, reducing production times and costs.

With the continuous advancements in technology, the impact of CNC lathes on modern production is expected to only grow in the years to come, transforming the way products are made and setting new standards for quality and innovation in the manufacturing sector.